PROJECTS

Patient-Specific Implants and Tools

How 3D imaging and printing are reshaping complex joint surgery

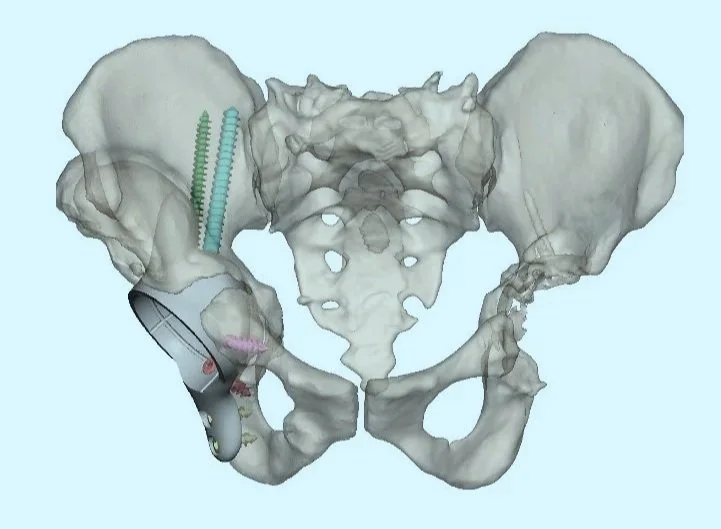

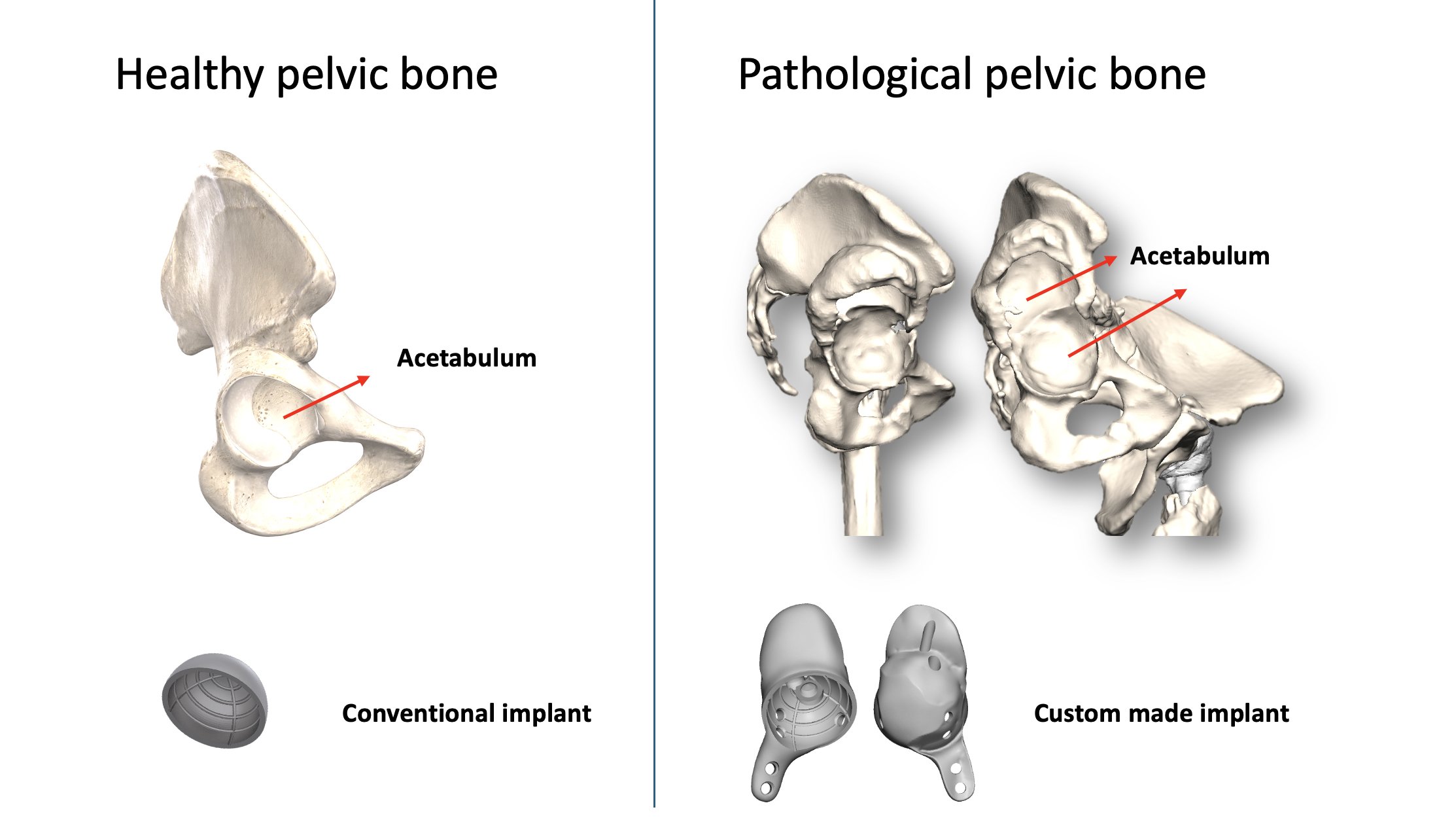

When joint damage is severe—especially after previous surgeries—standard implants often don’t fit well enough to restore function. Advances in CT scanning and image processing now allow us to create custom implants that match the individual’s anatomy, even in the most complex cases. We also design patient-specific surgical tools to help surgeons translate pre-operative plans into precise outcomes in theatre.

How we personalise implants and tools for complex cases

PATIENT-SPECIFIC INSTRUMENTATION (PSI)

Custom surgical guides tailored to the patient’s anatomy

Help surgeons reproduce the pre-operative plan more accurately

Improve alignment, precision, and confidence in challenging cases

OVERCOMING IMAGING CHALLENGES IN REVISION SURGERY

Previous metal implants can distort CT scans (known as artefacts)

We use carefully timed imaging—such as scanning after implant removal—to get clean, usable 3D models

This allows us to design custom implants even when bone loss is severe or distorted

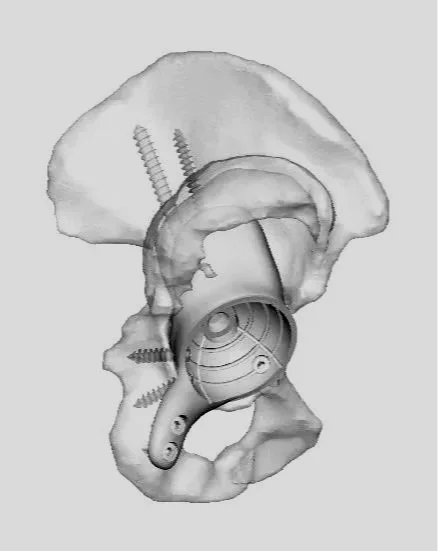

CUSTOM 3D-PRINTED IMPLANTS

Created from detailed CT scans of the patient’s bone

Designed to address complex bone defects and anatomical challenges

Include porous structures to promote bone integration and long-term stability

Rebuilding complex defects with custom implants

When the hip socket (acetabulum) is badly damaged—often due to injury or multiple previous surgeries—it becomes extremely difficult to rebuild using off-the-shelf implants. These cases require a tailored approach to restore stability and mobility.