CASE STUDY

Rebuilding complex hip defects with custom implants

When the hip socket (acetabulum) is badly damaged—often due to injury or multiple previous surgeries—it becomes extremely difficult to rebuild using off-the-shelf implants. These cases require a tailored approach to restore stability and mobility.

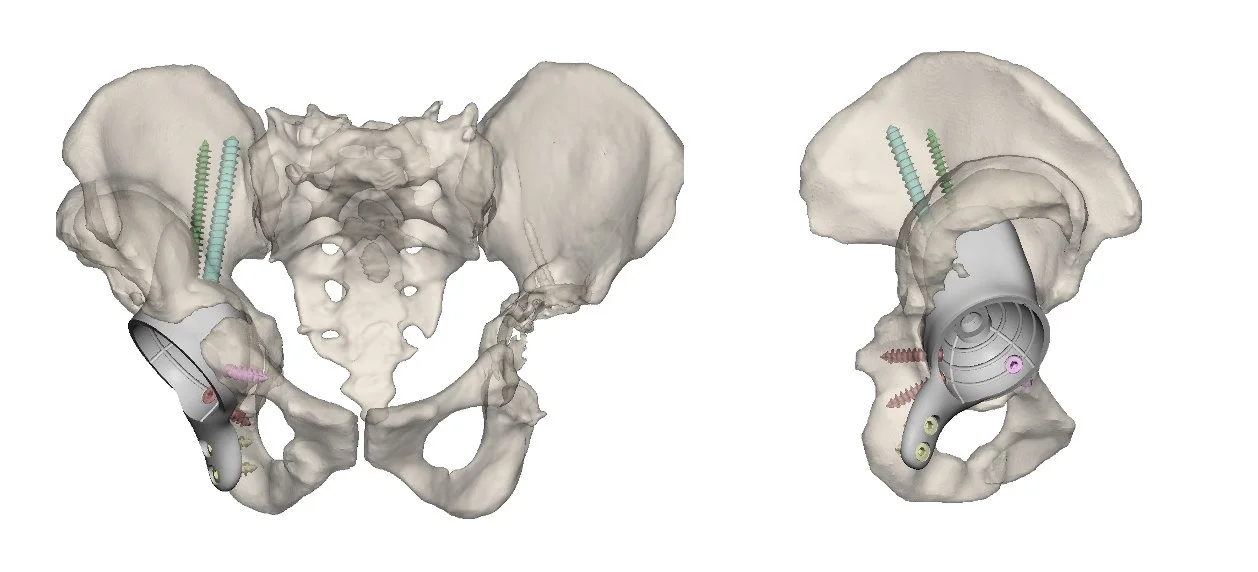

A precise understanding of complex hip defects allows engineers and surgeons to design custom implants that securely anchor to the patient’s remaining bone. By tailoring the shape and fixation strategy to each individual, these implants help restore joint stability, improve function, and offer reliable solutions in cases where standard components cannot achieve a stable fit.

The challenge

When the hip socket (acetabulum) is badly damaged—often due to injury or multiple previous surgeries—it becomes extremely difficult to rebuild using off-the-shelf implants. These cases require a tailored approach to restore stability and mobility.

Our solution: tailored to fit

Using high-resolution CT scans, we designed custom 3D-printed acetabular implants shaped precisely to each patient’s remaining bone. By designing implants directly from patient-specific imaging, we aim to:

Maximise bone–implant contact

Optimise fixation strategy (screw trajectories, flanges, buttresses)

Restore hip centre of rotation and biomechanics

Achieve reliable primary stability to support long-term osseointegration

Clinical Evindence

We have reported promising intermediate- and longer-term outcomes for custom acetabular implants in complex revision THA:

Intermediate-term results demonstrated significant improvements in functional outcomes, including Oxford Hip Scores, with stable radiographic fixation and evidence of osseointegration in the majority of cases (JBJS Open Access, 2023).

Minimum 5-year follow-up has shown sustained implant survivorship and durable clinical outcomes in patients undergoing complex revision with custom-made acetabular components (JBJS, 2026).

We have quantified the accuracy of custom acetabular component positioning by comparing pre-operative plans with postoperative CT scans, demonstrating that custom implants can be reliably reproduced within clinically acceptable tolerances in six degrees of freedom — including centre of rotation, inclination, and version — when grounded in precise 3D imaging and planning (J Orthop Res, 2020).

For the most severe defects (Paprosky >3B), our work has highlighted the critical role of functional imaging in guiding reconstruction and restoring biomechanics (BMC Musculoskeletal Disorders, 2021).

Together, these studies show that custom acetabular implants can be clinically effective, durable, and reproduciblewhen supported by rigorous imaging and planning.

Why it matters

Our work demonstrates that combining advanced imaging, computational modelling, and patient-specific implant design allows acetabular reconstruction to be tailored to the individual rather than the average.

By understanding anatomical variation and translating it into personalised implant geometry and fixation strategies, custom acetabular implants can restore biomechanics, achieve stable fixation, and deliver durable clinical outcomes in cases where conventional solutions fail.

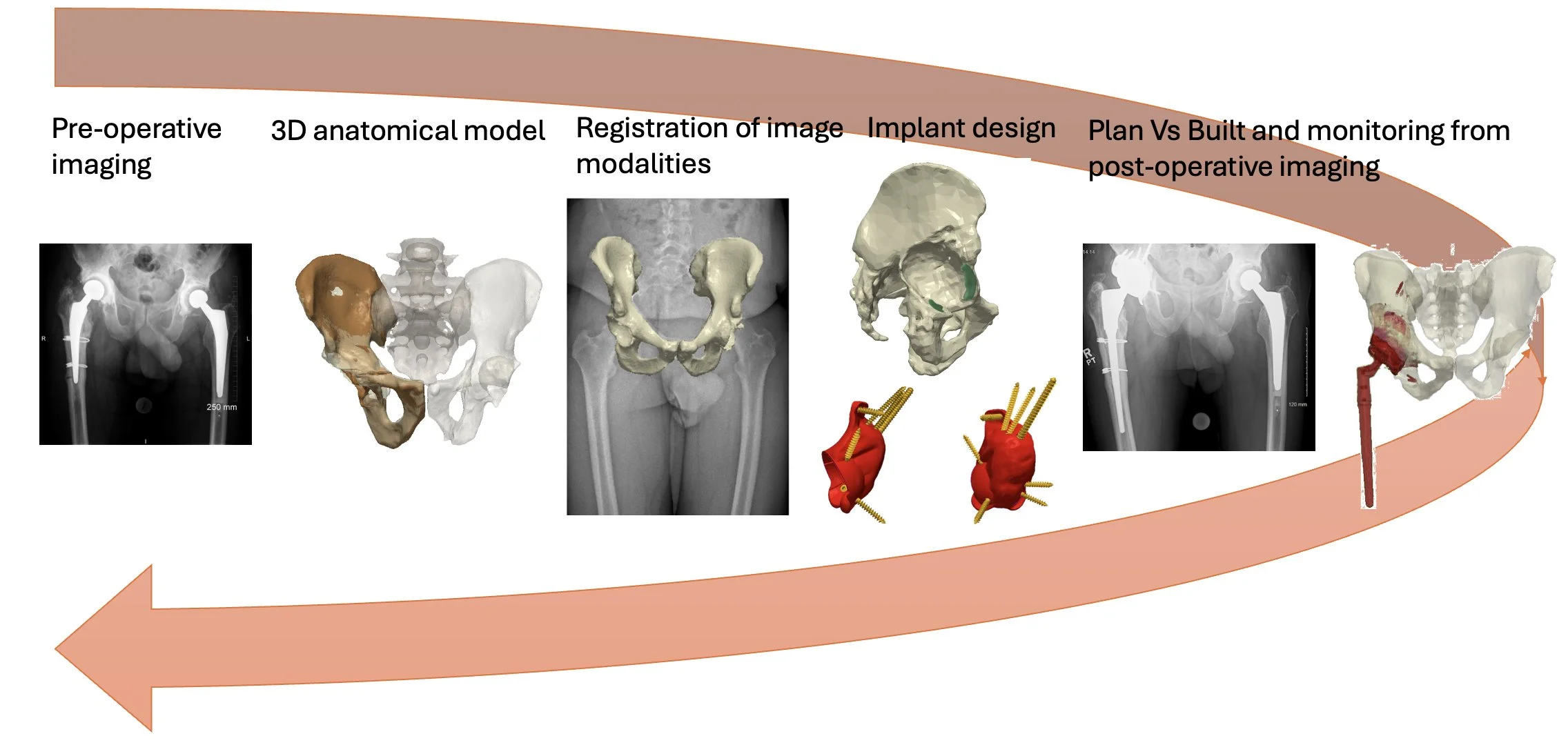

From imaging to implant design

Read the articles

Our workflow integrates advanced imaging, computational modelling, and close surgeon–engineer collaboration:

High-resolution CT imaging is used to generate detailed 3D reconstructions of the pelvis and acetabular defect

Advanced segmentation techniques are applied to minimise the impact of metal artefact from existing implants

Functional imaging and anatomical landmarks are incorporated to guide implant orientation and fixation planning

Patient-specific implants are designed tailored to the individual defect morphology

Intra-operative checks confirm alignment and positioning, and the insights gained feed back into the next planning cycle—refining models, improving accuracy, and continually advancing future surgical strategies.