CASE STUDY

Creating custom hip implants despite imaging challenges

Accurate imaging is crucial for designing a custom implant, but two major challenges can affect this process: metal artefacts from earlier implants, which distort CT scans, and the fact that scans are typically taken with patients lying down, not in functional weight-bearing positions.

Both issues can obscure the true anatomy and make it harder to design an implant that fits securely and performs well during real-life movement. Addressing these imaging limitations is essential for successful personalised reconstruction.

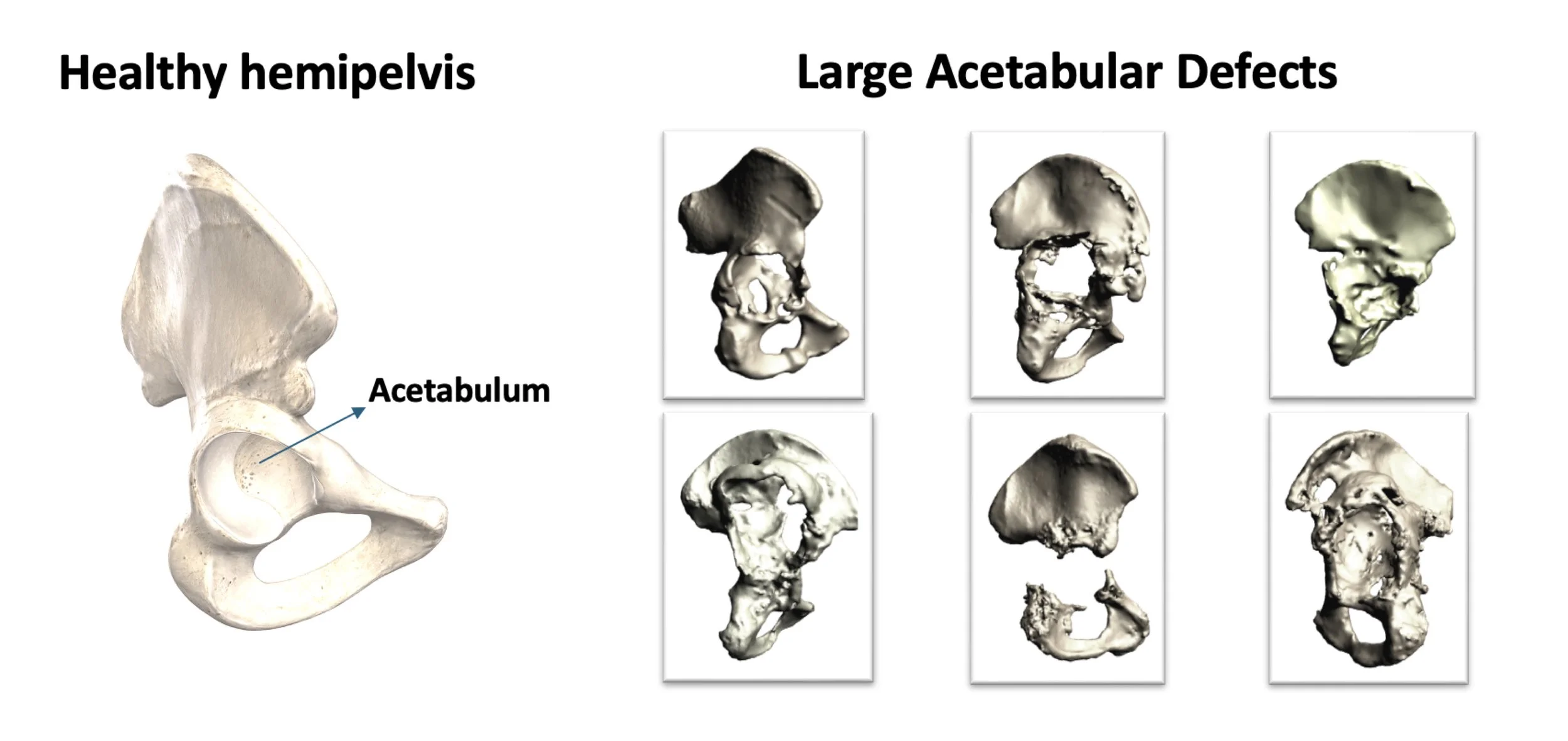

The challenge

Designing custom hip implants for revision surgery is complicated by two key imaging limitations. First, metal components from previous implants can obscure the true shape of the remaining bone on CT scans. Second, these scans are taken with the patient lying down, which does not reflect how the pelvis behaves in functional, weight-bearing positions.

Our solution: tailored to fit

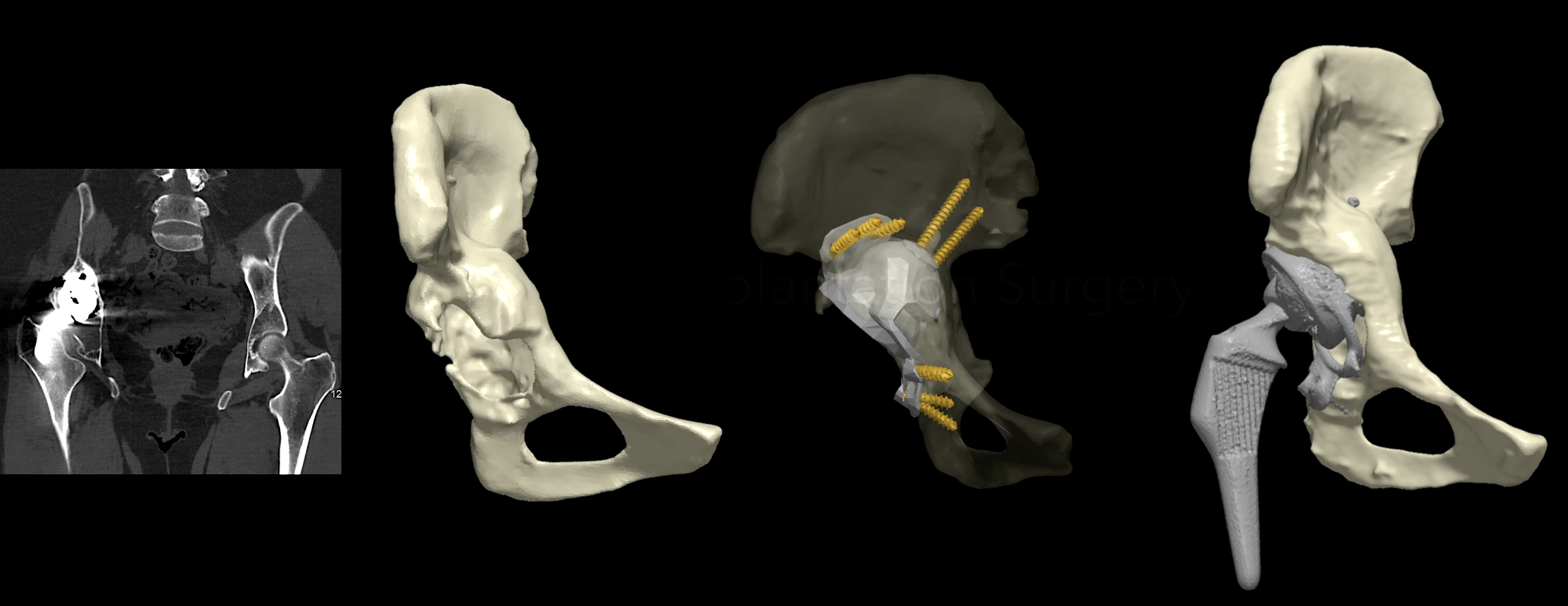

By analysing cases where implants were removed as part of necessary treatment, we were able to compare pre-operative imaging with the real, post-removal bone anatomy.

This allowed us to understand the combined impact of metal artefacts and surgically altered bone on the accuracy of custom implant design. Using this knowledge, we refine our modelling workflows to better anticipate these discrepancies and create designs that remain reliable even when anatomy is complex or has changed significantly.

Why it matters

Appreciating the combined impact of metal artefacts, surgically altered bone, and non-functional imaging helps us build more reliable personalised implants. Accounting for these factors early in the design process reduces the risk of mismatch during surgery, improves the likelihood of achieving a stable and well-aligned reconstruction, and ultimately supports better outcomes for patients undergoing challenging revision procedures.