CASE STUDY

Using 3D-printed custom tools to help surgeons place hip implants more accurately

Positioning of the femoral stem during hip replacement — especially achieving the correct femoral version and osteotomy level — is highly variable when using conventional, freehand methods. This variability risks poor implant orientation, instability, uneven load distribution, and suboptimal joint function

The challenge

In hip replacement surgery, the metal stem inserted into the thigh bone must be positioned at the correct angle (called the femoral version) to ensure good joint function and reduce complications like dislocation.

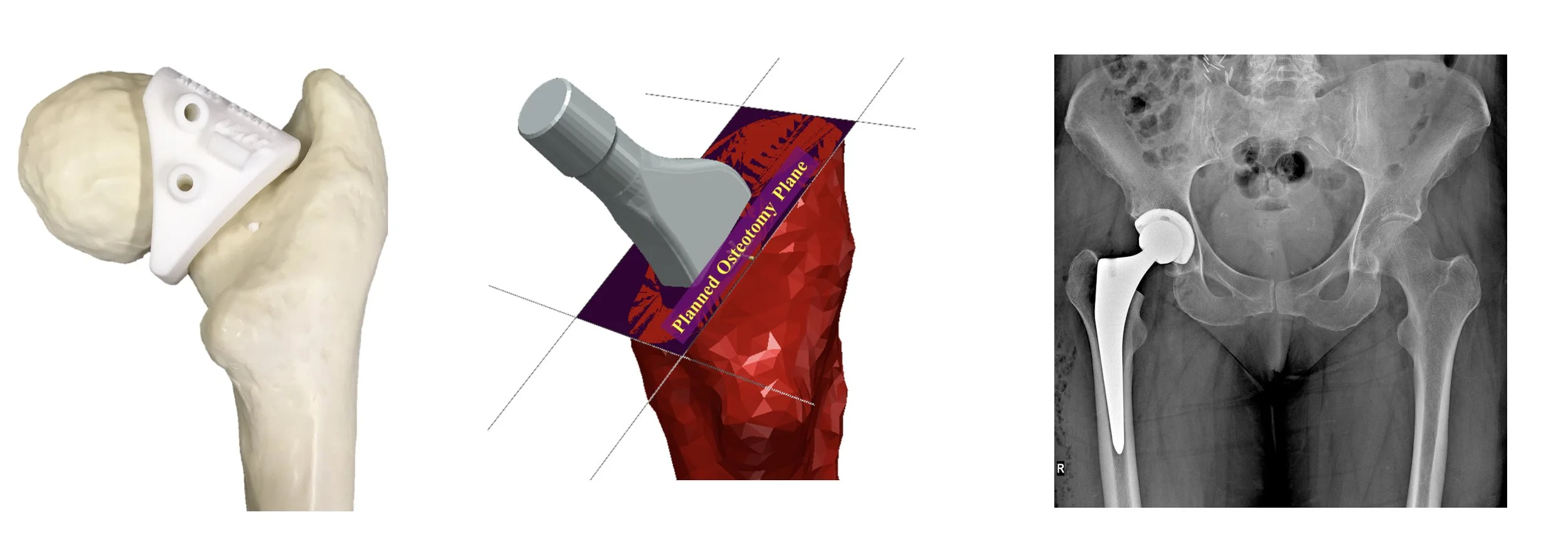

Our solution: patient-specific guides

We use patient-specific instrumentation (PSI) created from detailed pre-operative CT scans to guide two key steps of hip replacement surgery: the femoral neck osteotomy and the positioning of the femoral stem. These 3D-printed guides are designed to match each patient’s unique anatomy, helping surgeons reproduce the planned cut plane and achieve the intended stem orientation more reliably than with traditional freehand methods. By bringing the virtual surgical plan directly into the operating theatre, PSI provides a more precise and consistent way to execute critical stages of the procedure.

For cemented techniques, improving control over stem rotation can enhance joint mechanics and reduce the risk of complications related to malalignment. PSI provides a more reliable way to achieve the intended version, supporting better functional outcomes and greater consistency across surgeries.

What we found and why it matters

More accurate implant positioning supports optimal biomechanics, reduces the risk of dislocation or abnormal wear, and may improve long-term stability — ultimately enhancing patient outcomes. Because the method bridges virtual planning with real-world execution, it represents a meaningful step toward personalised, reproducible and cost-effective hip surgery.